OUR MACHINING SERVICE FACILITIES LIST OF EQUIPMENTS (2012)

Production Facilities

| No | Model | Brand | Detail | Units |

| 1 | Late 1′ | <SHUN-LIHN ” Taiwan> | DIA Ø 0-50 mm. L 100 mm. | 1 Units |

| 2 | Late 5′ | <TANAKA ” JP.> | DIA Ø 0-200 mm. L 750 mm. | 1 Units |

| 3 | Late 6′ | <YAM ” Taiwan> | DIA Ø 0-300 mm. L 1000 mm. | 1 Units |

| 4 | Late 7’ | <HER-LIH ” Taiwan> | DIA Ø 0-300 mm. L 1000 mm. | 1 Units |

| 5 | Late 7’ | <MAZAK ” JP.> | DIA Ø 0-350 mm. L 1000 mm. | 1 Units |

| 6 | Centerless200 mm. | <YUAN FU ” Taiwan> | DIA Ø 0-50 mm. L 200 mm. | 1 Units |

| 7 | Centerless300 mm. | <PAMALRY ” Taiwan> | DIA Ø 0-70 mm. L 300 mm. | 1 Units |

| 8 | Precision Internal Grinder | <JUNGBERLIN”JP.> | DIA Ø 0-300 mm. L 300 mm. | 1 Units |

| 9 | Precision External Grinder | <TOYODA ” JP.> | DIA Ø 0-400 mm. L 1000 mm | 1 Units |

| 10 | Precision External Grinder | <TOYODA ” JP.> | DIA Ø 0-500 mm. L 1100 mm | 1 Units |

| 11 | Precision Internal Grinder | <JAGURA ” TW.> | DIA Ø 0-25 mm. L 50 mm. | 1 Units |

| 12 | Precision External Grinder | <JAGURA ” Taiwan> | DIA Ø 0-30 mm. L 80 mm. | 1 Units |

| 13 | Precision External Grinder | <JAGURA ” Taiwan> | DIA Ø 0-40 mm. L 100 mm. | 1 Units |

| 14 | Precision Surface Grinder | <KURODA ” JP.> | (HxWxL) 150x 150x 450 mm. | 1 Units |

| 15 | Precision Surface Grinder | <KURODA ” JP.> | (HxWxL) 150x 150x 450 mm. | 1 Units |

| 16 | Precision Surface Grinder | <NICCO ” JP.> | (HxWxL) 400x 600×1200 mm. | 1 Units |

| 17 | Precision Surface Grinder | <NICCO ” JP.> | (HxWxL) 800x1200x2000 mm | 1 Units |

| 18 | Precision Surface Grinder | <HITACH ” JP.> | (HxWxL) 1000x2300x3200 mm. | 1 Units |

| 19 | Milling Machine | <BITBORDE ” JP.> | (HxWxL) 200x 300x 800 mm. | 1 Units |

| 20 | Milling Machine | <HITACHI SEIKI” JP.> | (HxWxL) 200x 350x 700 mm. | 1 Units |

| 21 | Milling Machine | <ENSHU ” JP.> | (HxWxL) 200x 350x 800 mm. | 1 Units |

| 22 | Milling Machine | <ENSHU ” JP.> | (HxWxL) 200x 450x 900 mm. | 1 Units |

| 23 | Milling Machine | <RAMBO ” Taiwan.> | (HxWxL) 250x 300×1200 mm. | 1 Units |

| 24 | Milling Machine | <RAMBO ” Taiwan.> | (HxWxL) 250x 300×1200 mm. | 1 Units |

| 25 | Milling Machine | <TANTAI ” Taiwan.> | (HxWxL) 250x 350×1250 mm. | 1 Units |

| 26 | Milling Machine | <TANTAI ” Taiwan.> | (HxWxL) 250x 350×1250 mm. | 1 Units |

| 27 | Milling Machine | <TANTAI ” Taiwan.> | (HxWxL) 250x 350×1250 mm. | 1 Units |

| 28 | BedType Milling Machine | <OHTORI ” JP.> | (HxWxL) 250x 450×1000 mm. | 1 Units |

| 29 | BedType Milling Machine | <OHTORI ” JP.> | (HxWxL) 250x 500×1100 mm. | 1 Units |

| 30 | BedType Milling Machine | <OHTORI ” JP.> | (HxWxL) 500x 600×1500 mm. | 1 Units |

| 31 | BedType Milling Machine | <OKK ” JP.> | (HxWxL) 300x 500×1200 mm. | 2 Units |

| 32 | PlanoMilling Machine | <MARUFUKU ” JP.> | (HxWxL) 600x1200x3000 mm. | 1 Units |

| 33 | PlanoMilling Machine | <MARUFUKU ” JP.> | (HxWxL) 1000x2300x4000 mm. | 1 Units |

| 34 | CNC Machining Center | <MORI SEIKI ” JP.> | (HxWxL) 400x 400x 600 mm. | 1 Units |

| 35 | CNC Machining Center | <OKK ” JP.> | (HxWxL) 450x 450x 600 mm. | 1 Units |

| 36 | CNC Machining Center | <OKK ” JP.> | (HxWxL) 450x 450x 600 mm. | 1 Units |

| 37 | CNC Machining Center | <HITACHI SEIKI” JP.> | (HxWxL) 450x 500x 600 mm. | 1 Units |

| 38 | CNC Machining Center | <LILIAN ” Taiwan> | (HxWxL) 550x 640×1050 mm. | 1 Units |

| 39 | CNC Machining Center | <HARTFORD”Taiwan> | (HxWxL) 820x 800×1600 mm. | 2 Units |

| 40 | CNC Late Machine X-150 | <TAKAMAZ ” JP.> | DIA Ø 0-300 mm. L 300 mm. | 1 Units |

| 41 | Heat Treatment Furance MAX TEMP. 1300 ‘ C | 2 Units | ||

| 42 | Wide Cut Machining | 1 Units | ||

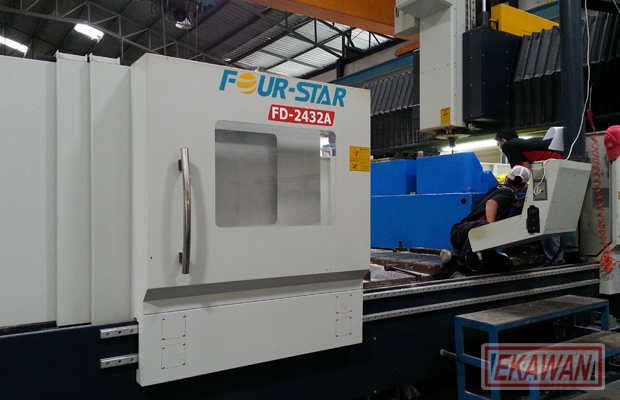

| 43 | CNC Double Column Machining | <FourStar”Taiwan> | (HxWxL) 1200x2400x3200 mm. | 1 Units |

LIST OF QUALITY CONTROL EQUIPMENTS (2014)

Production Facilities

| No | Model | Units |

| 1 | Go-No Go Gauges | Various |

| 2 | Master Pin and Ring Gages | Various |

| 3 | Digit Outside Micrometer | 0-300 mm. |

| 4 | Inside Micrometer | 2-500 mm. |

| 5 | Vernier Caliper | 0-1500 mm. |

| 6 | Blade Micrometer | 0-300 mm. |

| 7 | Depth Micrometer | 0-300 mm. |

| 8 | Gauge Block Set | 1 set |

| 9 | Granite Surface Plate | 1 set |

| 10 | Taper Gauges | 1 set |

| 11 | Snap Gauges | 1 set |

| 12 | Pin Gauges | 1 set |

| 13 | Digimatic Height Gages (300 mm.) | 1 units |

| 14 | Digimatic Height Gages (600 mm.) | 1 units |

| 15 | Rockwell Hardness Tester (เครื่องเช็คค่าความแข็ง ) | 1 units |

| 16 | LayOut Machine (1200x1500x2400 mm.) | 1 units |

| 17 | LayOut Machine ( 800x1000x2400 mm.) | 1 units |

| 18 | FARO Edge Arm (2700 mm.) 7 Axis | 1 units |

| 19 | Kreon ACE Arm (3000 mm.) 7 Axis | 1 units |